Member Highlight

Synagro: Stepping up renewable energy generation from waste heat

January 2015

Southern New England's wastewater treatment infrastructure relies on thermal conversion (incineration) for disposal of wastewater solids. This solids management solution was established with large infrastructure investments in the 1980s, when the U. S. EPA and state agencies provided extensive capital funding for wastewater infrastructure.

Ever since, Connecticut and Rhode Island have relied primarily on incinerators, many of which provide efficient, regional solutions by taking in solids from many different water resource recovery facilities (WRRFs) in addition to processing solids from the local community. Synagro operates two of these major merchant incinerators: at New Haven, CT and Woonsocket, RI.

Since the mid-2000s, Synagro has installed heat recovery systems that put to use the excess heat from these thermal conversion facilities. In 2009, the company started generating electricity at the Greater New Haven Water Pollution Control Facility. And, despite some technical challenges, the company is now producing half a megawatt of renewable energy there – from a resource (heat) that used to be wasted. Meanwhile, at its Woonsocket facility, Synagro is now generating 1.2 megawatts or more from the 105 dry tons/day of wastewater solids delivered to the facility from the neighboring WRRF and other WRRFs.

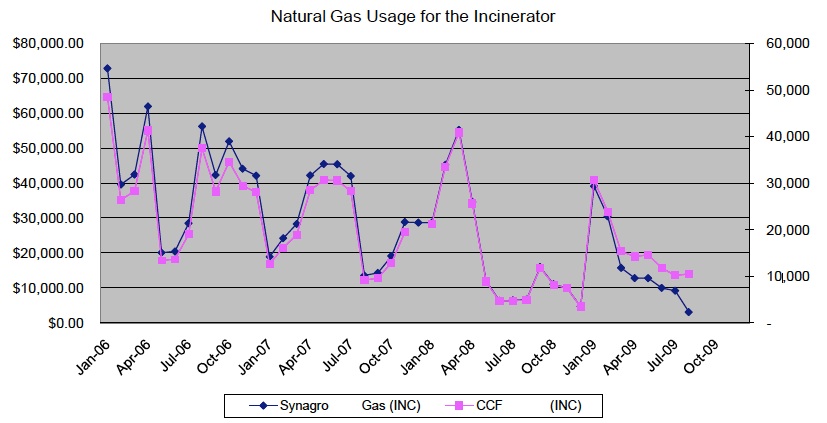

An important part of the efficiency of operations at both facilities is the inclusion of fats, oils, & grease (FOG) as fuels in the incineration process. These high-energy "wastes", pumped from restaurant grease traps, offset some of the non-renewable natural gas necessary to combust wastewater solids. By taking in FOG, the facilities are managing a challenging waste, generating some income from tipping fees, and reducing their natural gas consumption (graph below).

Using FOG as fuel reduces natural gas use & costs at the New Haven incinerator.

Wastewater solids delivered to the New Haven incinerator.

New Haven's new solids management system.

The Woonsocket, RI wastewater solids incinerator.